What are hot dip galvanized driven steel pipe piles? Special supports which are used to ensure the safety and stability of buildings or other types of structures. These piles consist of high tension steel tubes. They way these work is quite unique as well. With a large hammer, these tubes were pushed under the ground. And when they get pushed down far enough, the material becomes strong and hard enough to carry the weight of all kinds of heavy things—houses or schools—even bridges.

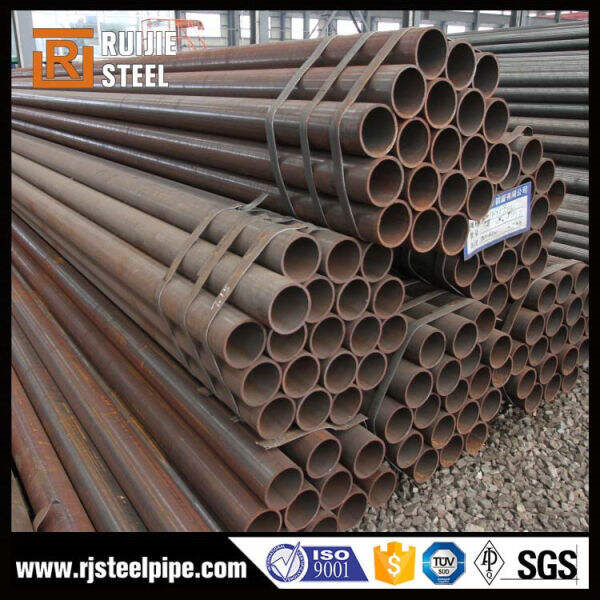

The steel pipes and tubes which is driven are very strong and they can reckon a huge weight. So, they do not bend or break easily and this is very important for the strength of buildings. They are not only stain proof but also crafted to be corrosion resistant. Rust is a result of metal getting wet, and it can eventually wear the material down. Because these piles are non-ferrous and will not rust, they can truly last for generations without the need to be changed out. So you can use them if durability is your main focus.

If you are constructing something requiring a large support system, driven steel tube piles are great. They can support all sorts of things ( e. g., high-rises, bridges and even multi-story parking garages. Very large piles which reaches the ground make a very sturdy foundation that retains everything secure and in equilibrium. This stability is important in areas with soft or uneven ground steel and pipe will guarantee that your building stays safe and strong for years.

Driven steel tube piles are created with the unique sole intention of providing ultimate support to all your construction requirements; They are carefully constructed to maximize the strength and stability of your projects. Driven steel tube piles are engineered to high standards for quality, providing you with a superior foundation. Make sure your building is safe, order driven saw steel pipe online today.

Indeed, when it comes to that perfect foundation for your construction project; driven steel tube piles remain the ideal choice. They are durable, they work for a long period of time and can carry heavy loads without any struggle. This is why you can trust these piles to protect all types, shapes and sizes of building. Therefore, when you begin to construct your project then do consider using driven black steel pipe. They will make sure that your project is solid and holds up in the long run.

Our steel tube factory places quality at the top of everything we do. We adhere to the strictest international standards of quality and employ an efficient management system for quality throughout the production process. We make sure that each steel tube meets or above the customer's expectations, right from the meticulous test of raw materials to rigorous testing of the final product and in-processing. Steel tubes are renowned for their strength, durability and Driven steel tube piles. Our precision engineering combined with high-grade materials, advanced manufacturing techniques and our focus on precision engineering result in steel tube that is renowned for its durability, strength and dimensional precision.

The steel tube plant we operate stands out for its automated production systems that revolutionize manufacturing. We utilize the latest technology to streamline every step starting with the raw materials handling and packaging the final product, reducing Driven steel tube piles and maximizing throughput. This degree of automation ensures a consistent and swift production cycles but also enables immediate monitoring and adjustment which optimizes resource allocation and reducing the amount of downtime. We are able, as consequence, to respond quickly to changes in the market and also to complete massive orders with a high degree of precision. This sets new standards for productivity.

we're Driven steel tube piles to be able to provide specific solutions for steel tubes our highly skilled rd and customizing team works closely with customers to learn about their individual needs in developing custom alloys to meet the demands of extreme environments creating precise dimensions or using specialized coatings this degree of personalization along with our extensive understanding of the market and our expertise will allow us to offer steel tubes that are ideally suited to the unique challenges and demands of each project creating long-term partnerships and driving forward the development of technology in the market

At our steel tube factory, we are deeply committed to the protection of the environment and support sustainable practices. We understand that responsible manufacturing isn't just good for the planet but also essential for our long-term growth. To achieve this we have invested in cutting-edge technology and processes to reduce our carbon footprint and improve efficiency in energy use. From implementing recycling and waste reduction initiatives to using equipment that consumes less energy and renewable energy sources, we constantly strive to increase our environmental efficiency. Our sustainable approach is not only a catchy slogan, but rather it is a fundamental principle that guides every decision we make, ensuring that we Driven steel tube piles a positive impression for future generations.